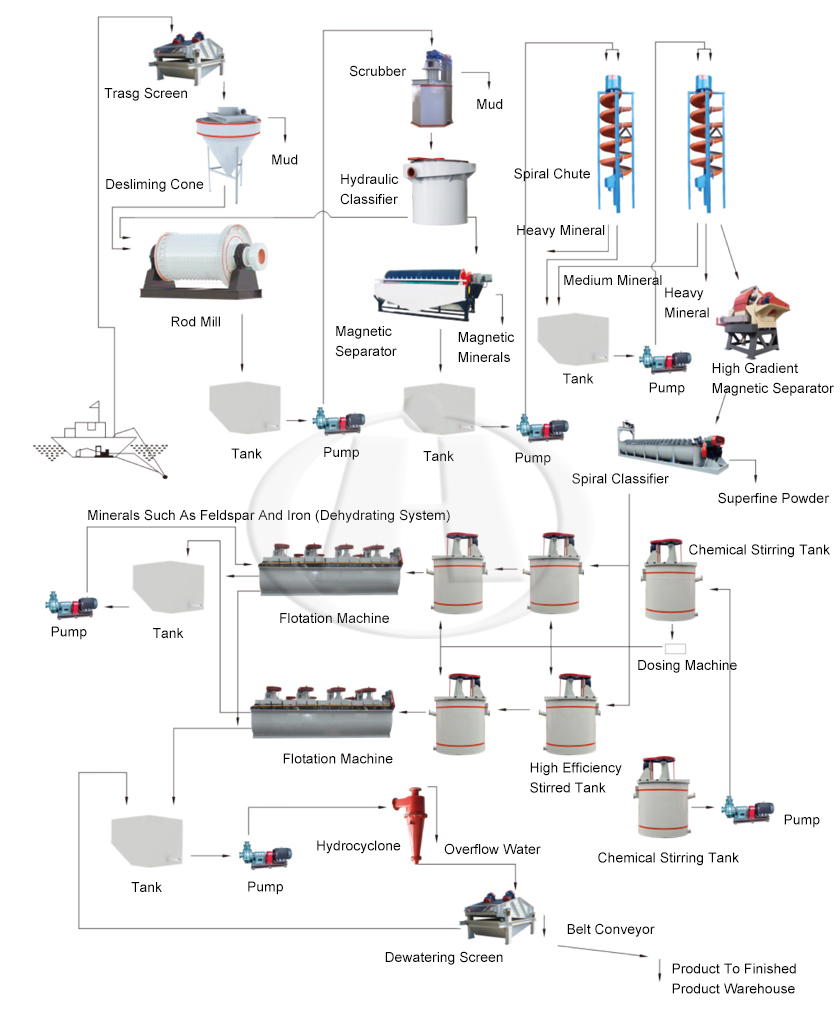

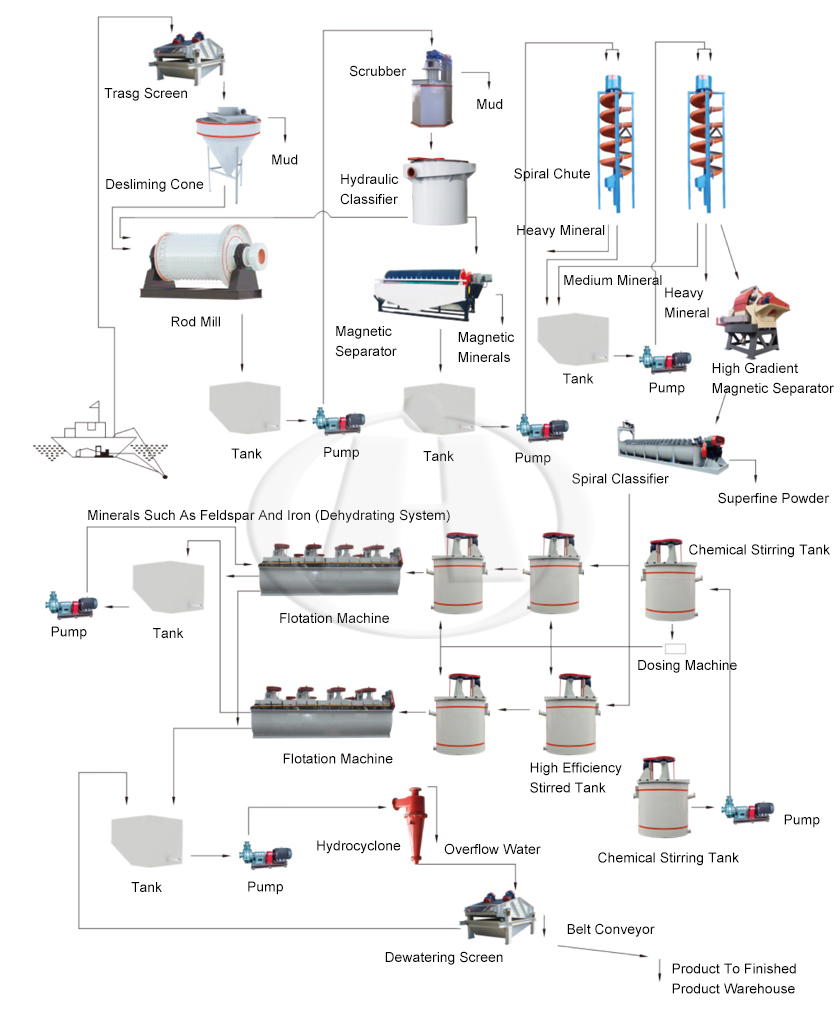

Quartz sand is a type of industrial sand that is produced from quartzite rocks or quartz deposits. It is composed of silicon dioxide (SiO2) and has a high silica content, typically above 95%. Quartz sand is characterized by its high purity, hardness, and chemical resistance, making it an ideal material for various industrial applications. Quartz sand production involves several stages of processing, including crushing, grinding, screening, washing, and drying. The main equipment: Crushers, Ball Mill,Scrubbers, Magnetic Separators, Flotation Machines, Acid Leaching Tanks, Drying Equipment, etc.

Applied material:sandstone, quartzite, vein quartz deposits, and etc.

Quartz Sand Processing Flow:Crushing、Grinding、Purification、Concentration.

.jpg)