● Suitable for dry ultrafine grinding of various materials with a Mohs hardness below 9.

● Because the material is crushed by self-collision driven by the airflow, it will not cause pollution during the material crushing process.

● Because the material is crushed in a state of gas expansion, the temperature inside the crushing chamber is controlled at room temperature.

● With a built-in grading device, the desired product particle size can be obtained at one time.

● The equipment can be made with wear-resistant protection, such as ceramic, polyurethane, wear-resistant rubber and other options.

● The equipment is easy to disassemble and clean, and the inner wall is smooth and free of contamination.

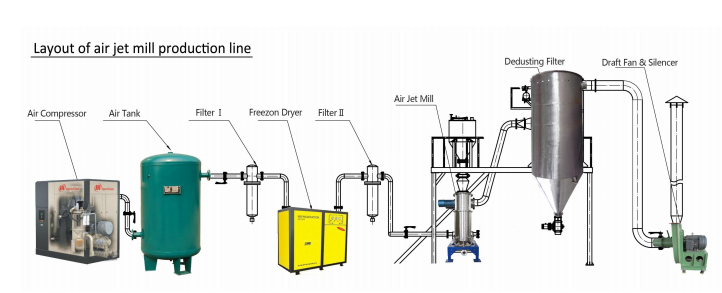

● The entire system operates in a closed manner, with low noise and a clean production process.